SBP: Rebuilding Homes and Lives After Disaster

Disaster can strike in a moment. The cleanup, though, often takes years.

In 2011, the Toyota Production System Support Center, TSSC, began working with SBP to speed up the recovery process in under-resourced communities. At the time, some victims of Hurricane Katrina were still homeless six years after the storm devastated New Orleans.

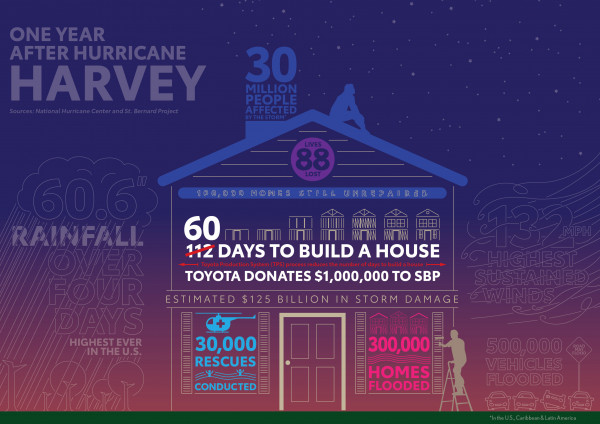

Toyota donated its expertise in the Toyota Production System (TPS), the underpinning of its successful manufacturing process, and worked with SBP to reduce the average time it took to rebuild a home from 116 days to 60 days—a 48-percent decrease in build time.

“We taught them principals that created efficiencies to rebuild homes, and they ran with it. They now apply it to everything they do and even share their know-how with other non-profits on the ground in disaster sites,” explains Mike Goss, president of the Toyota USA Foundation, general manager for Social Innovation at Toyota Motor North America and a current SBP board member.

Thinking Big

Today, SBP takes a holistic approach to disasters through five interventions. PREPARE home and business owners through resilience training; REBUILD efficiently; SHARE our model with other organizations; ADVISE municipal and state officials, and ADVOCATE for policy changes and improvements to the disaster recovery industry. The organization’s mission is to lessen suffering in crises such as floods, hurricanes and tornadoes by shrinking the time between disaster and recovery.

A need that’s only growing as incidents of extreme weather rise. Recent data projects more than 3.3 million people were displaced by flood, hurricanes, tornadoes and fires in 2022.

Improvements, once they begin, tend to invite others.

“We thought TPS meant ‘build faster.’ The beauty is the system changed the way we exist and think and breathe,” says Zack Rosenburg, SBP co-founder and CEO. Rosenburg began SBP with his wife, Liz McCartney, when the two left their jobs as a lawyer and teacher, respectively, in Washington D.C. to volunteer in New Orleans after Katrina struck the low-lying coastal city in 2005. They never left.

Rosenburg views the partnership in terms very much in line with the TSSC team’s hopes for every group they work with.

“Toyota helped us become much better at rebuilding home," he says. “But the biggest thing they did was teach us how to think. That’s the beauty of the partnership. Toyota changed our essence. Now, we’re able to meet a national mandate in a way that’s client centered. It’s empowering to our employees and volunteers.”

The Toyota Way

The “essence” that Toyota brought to the project was The Toyota Way, based on the company’s core philosophies of showing respect for people, working for others, and continuous improvement, or kaizen.

In addition, SBP is now able to build at 40 percent less than the cost of market-rate contractors by relying on AmeriCorps and volunteer labor. Through training and sharing resources to mitigate risk before a disaster and speed up recovery afterward, over 12 million people are reached annually.

With results like those, it’s easy to envision a day when storms may be met with a readiness never seen before, making it possible not only to shrink suffering further and further, but to make resilience the standard for all.